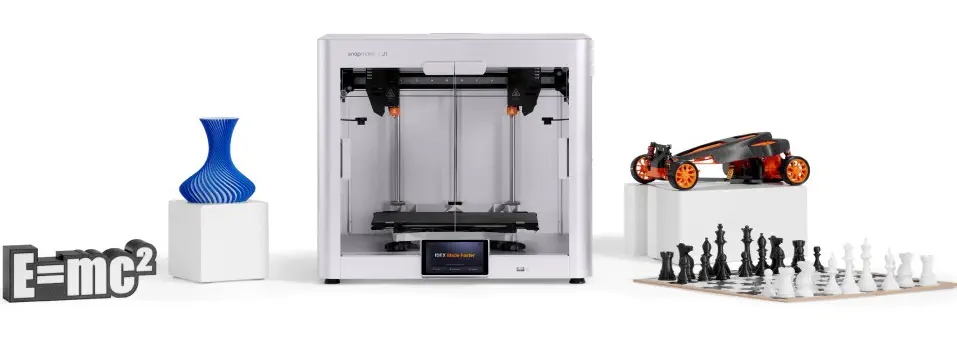

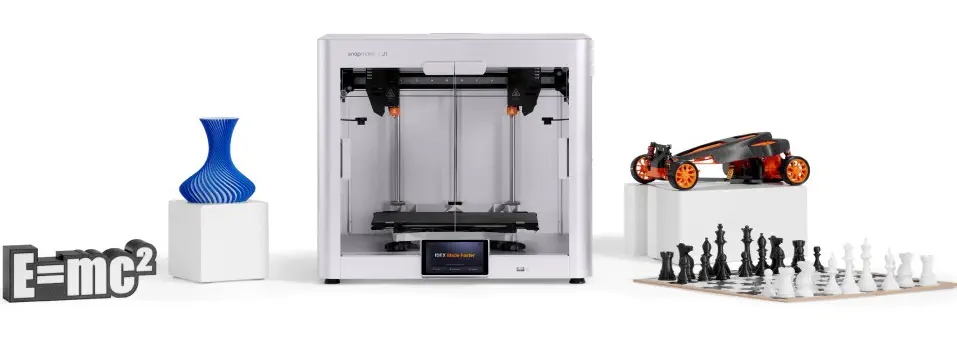

- Snapmaker J1s High Speed Dual Extruder (IDEX) 3D Printer

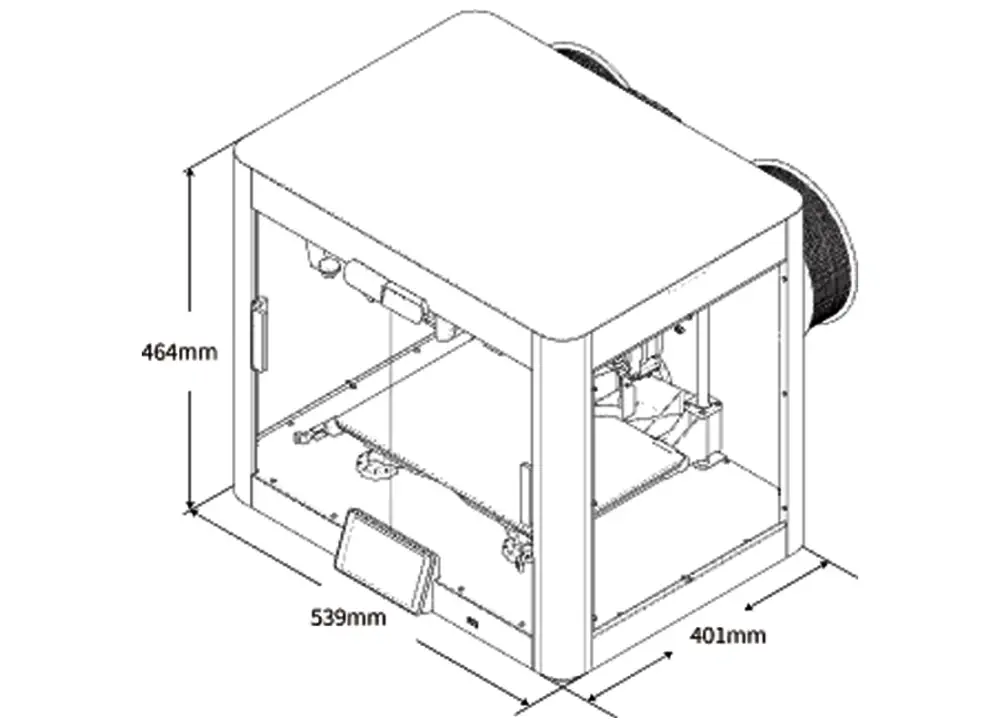

- Print volume 300 x 200 x 200 mm

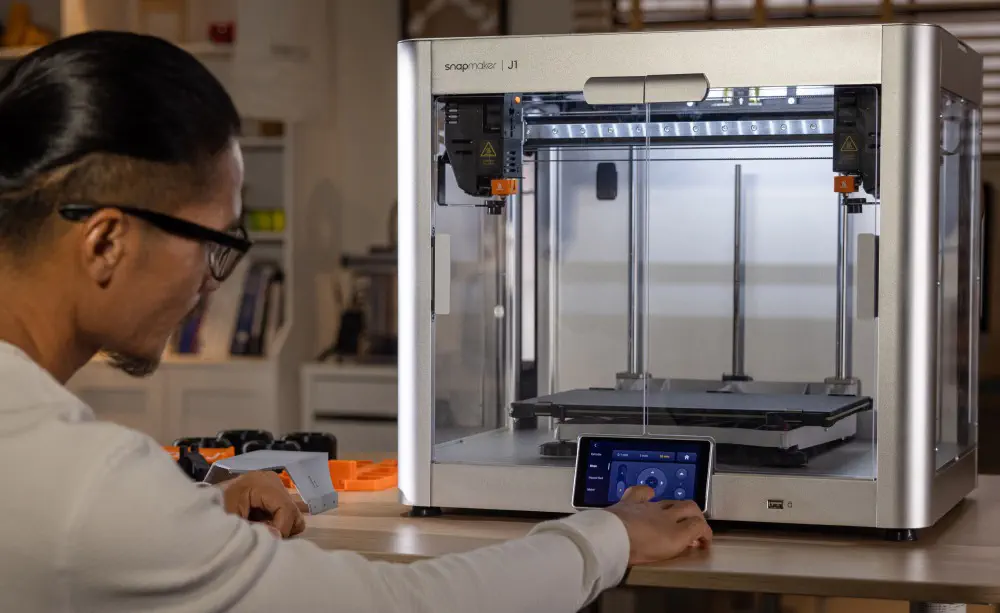

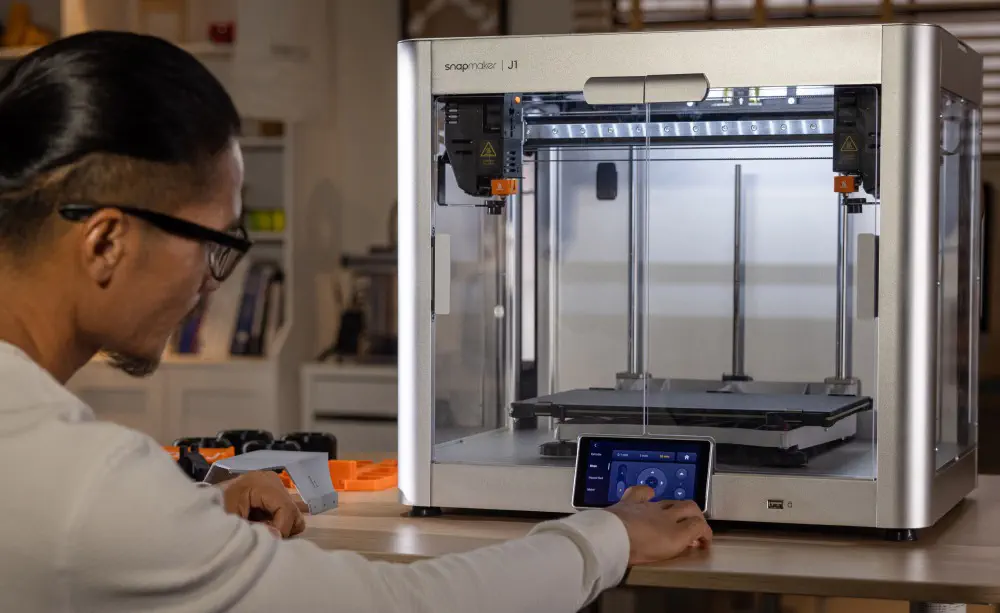

- Offers a 5-inch intuitive touchscreen

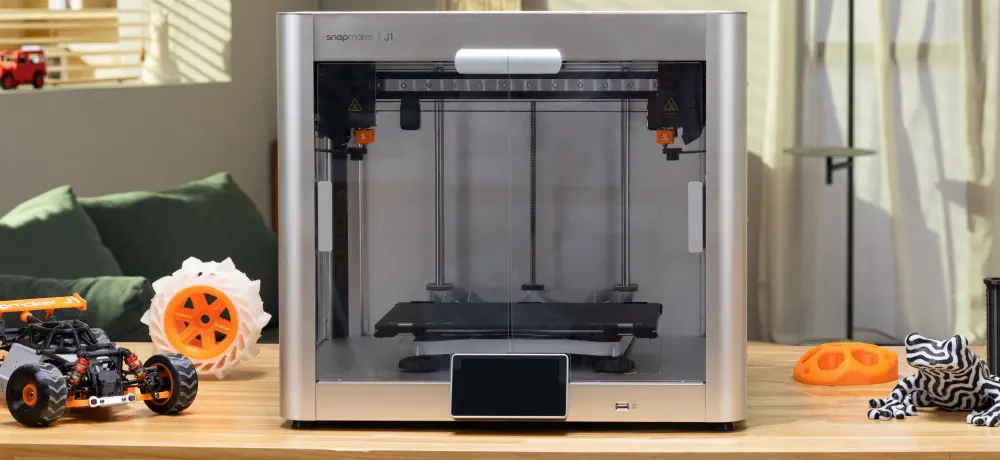

- Features independent dual extruder (IDEX)

- Built-in nozzle wipers

- Easy-swap hot ends with multi-diameters

- Double-sided PEI Glass Plate

- Breakaway and dissolvable supports

The Snapmaker J1s High Speed Dual Extruder (IDEX) 3D Printer features independent dual extruder (IDEX), ultra-fast print speed, and smoothing optimization. With cast and machined parts, linear rails, intuitive software, and user-centered designs, J1 is also refined and solid.

J1 brings you a top-of-class printing speed of 350 mm/s while ensuring a high resolution of prints. It is made possible by the optimization of the vibration compensation technology. This technology reduces the vibrations caused by high-speed movements, minimizing ringing to enhance print quality. With the maximum acceleration of 10,000 mm/s², you can realize small models packed with details with efficiency.

Seamless Extruders Switching

During dual extrusion printing, the non-working extruder preheats while on standby and starts printing right after the working extruder leaves, significantly reducing your waiting time.

Cornering Optimization

By analyzing the extruders' moving directions ahead of time, J1 is able to prevent problems like corner bulges, delivering better print quality at corners.

One-piece Die Casting

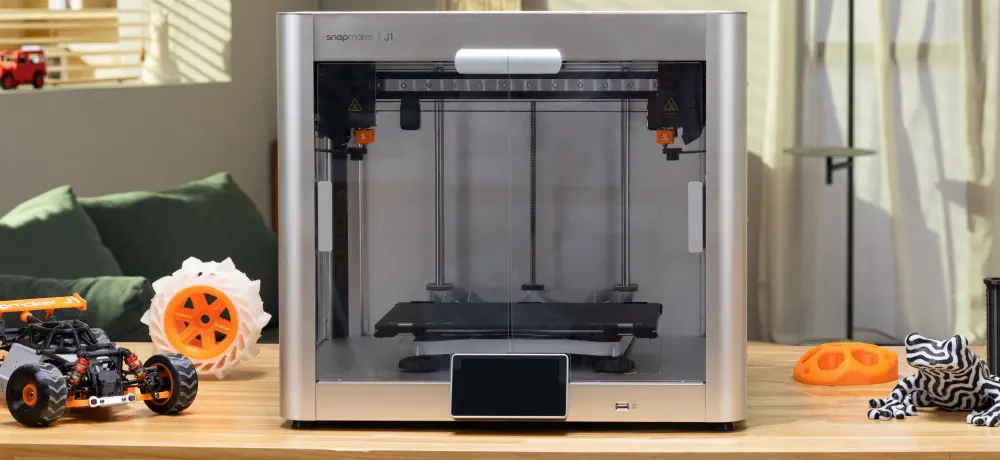

J1's body comprises an upper frame and a base made by one-piece die casting, and four aluminum alloy bars. Making the body with just a few highly integrated parts - an approach long adopted by the automotive industry - facilitates precision assembly. J1 is so rigid and reliable with minimal wobble and deformation possible that you can print large projects one after another for a long time and get all prints of uncompromising quality.

High-precision Linear Rails

The industrial-grade linear rails are made by CNC grinding at the micron level, ensuring smooth and steady movements. A significant rise in precision, rigidity, and durability for you to savor a fast, accurate, and steady-making experience.

Aluminum Alloy Frame

J1 inherits Snapmaker's iconic all-metal design which users highly value for its rigidity and durability. It provides better heat dissipation with the main board and power supply spread out on the base and aluminum alloy as its main material. All electronic components are well-oiled, at your command.

IDEXcel in Dual-material Printing

Compared with a multi-material unit, IDEX dual-material printing requires less time in a filament changing and creates less waste. Plus, IDEX offers the cleanest two-extruder solution that prevents cross-contamination. It creates a clean interface between two materials, embracing hassle-free removal and avoiding stains and weird blending along the seam.

Snap Removal, Smooth Finishes

Building and removing support can look like rocket science sometimes, but we've done the math for you–steady support, clean interface, effortless removal, and minimal post-processing needed to maintain high dimensional accuracy.

Breakaway Support

Breakaway filament offers the same support as normal materials but is much easier to remove without the need for further post-processing.

Dissolvable Support

J1 supports PVA and other dissolvable materials. Soak the print, and the supports dissolve, leading to a smooth surface and excellent dimensional accuracy. When you are looking for complex geometry, hollow structures, and exquisite details, this is for you.

300 °C Hot Ends

300 °C maximum nozzle temperature comes in handy when you print with high-temperature filaments, like nylon, reinforced nylon, and PC. With silicone hot-end socks preventing heat loss, filaments melting and heating up are much faster. Anti-clogging designs make the flow as smooth as possible.

Dual Direct Drive

Excellent extrusion accuracy aids in the extrusion of flexible filaments, along with the high responsiveness of dual direct drives to make deposition faster, smoother, and more accurately controlled. It is built in with a filament sensor to inform you and pause the print job in the case of filament runout, nozzle clogging, and other abnormalities that fail filament loading.

Compact Extrusion Path

The compact extrusion path of a unique design allows you to print seamlessly with TPU and many other flexible materials.

Enclosed Space

It provides stable ambient conditions to facilitate the consistently reliable performance of high-temperature materials. For instance, it keeps ABS and many other materials from warping.