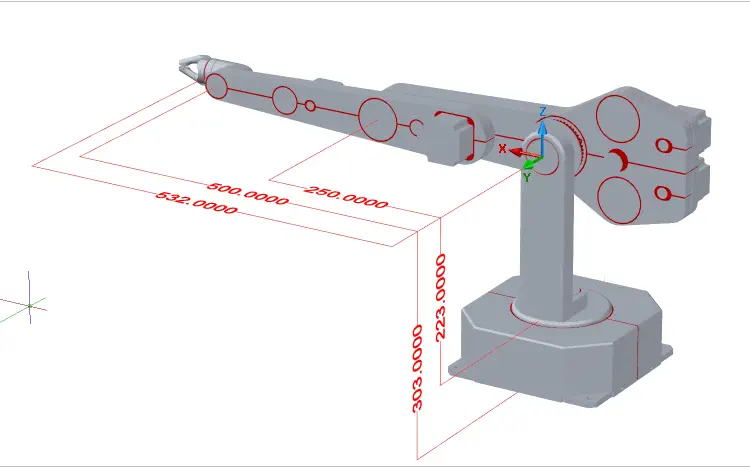

- 5-axis articulated robot arm w/ 500mm reach

- Easy mounting of tools, grippers, sensors etc

- Fully enclosed; pneumatics and wiring go through the arm

- Gripper sold separately (see options)

- Many options available

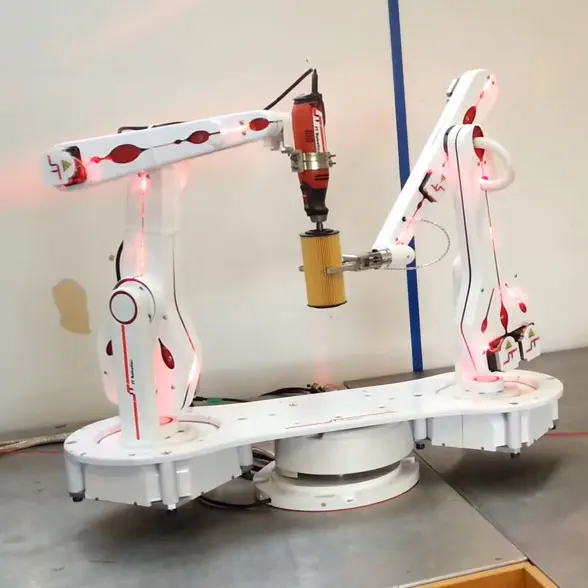

The ST Robotics R12 5-Axis Articulated Robot Arm is a self-contained five (optional six) axis vertically articulated robot arm system designed as a cost effective solution for bench top automation. aPossible pplications include testing, sample handling, machine feeding, etc... The hand ends with a mounting plate to which can be mounted one of the low cost grippers below (gripper sold separately), vacuum pickups or your own device.

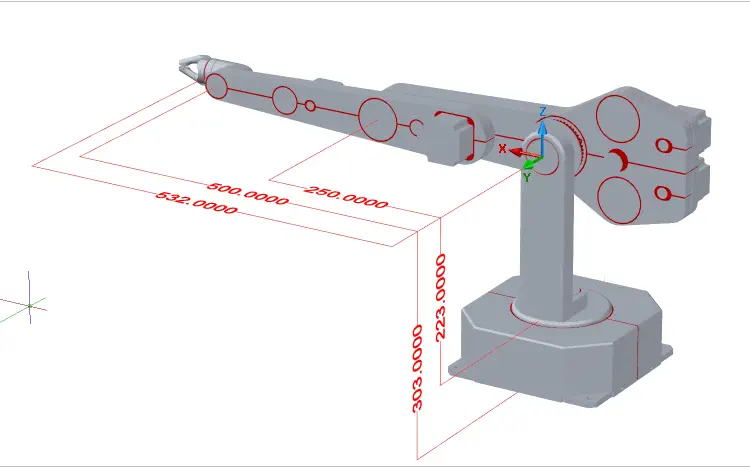

The ST Robotics R12 5-Axis Articulated Robot Arm is a very low cost entry to robotics, fast, accurate and reliable and easy to program yet capable of the most complex tasks. It has a useful 500mm reach. Like the ST Robotics R17 5-Axis Articulated Robot Arm , it is a 5 axis articulated robot arm but with a 500mm reach. It is lighter, faster and quieter, using high efficiency digital motors driving through steel reinforced polyurethane timing belts. Optional incremental optical encoders provide exceptional integrity as well as safety (see below).

The ST Robotics R12 5-Axis Articulated Robot Arm package includes the K11 controller that is simple and reliable using a partnership of CPU and DSP micro-processors and compact micro-stepping drives. ROBOFORTH II embedded software gets you started easily, yet allows the most complex motions, interfaces and peripherals to be programmed, assisted by ROBWIN project manager that brings everything together on one Windows screen.

Features:

- User friendly software, English language commands

- Input/output interfacing

- Non-volatile memory

- Complete with controller, software, on-screen manuals, cables, etc. Ready to go

- Optional pneumatic or electric grippers, vacuum pickup, tool changers.

- Supplied ready to run -- robot, controller, all cables, Windows GUI project manager, teach pad

- On-screen manuals

- Optional linear track, I/O expansion, bluetooth teachpad, TCP/IP

Options (sold separately, contact us for a quote)

Encoders

The role of the encoders in the R12 level 1 option is as a watchdogs. The loop is closed after completion of each individual motion which is not the same as servo control. The R12 encoder option includes miniature optical incremental encoders fitted to each axis.

Without encoders the R12 will run accurately and indefinitely open loop without error thanks to micro-stepping drives and accurate transmission. But if the robot suffers a collision then the controller does not know and carries on with the program even though the robot could be out of position. Such collisions usually only occur accidentally during programming and rarely during normal running. It is necessary to run the calibrate routine after such a collision. With the encoder option the controller notices the discrepancy immediately, stops the robot and announces an error.

If the encoder option is not fitted, a software solution is provided in the form of a quick calibration check that can be included in every robot cycle or n cycles. If there is an error it is reported and the system stops.

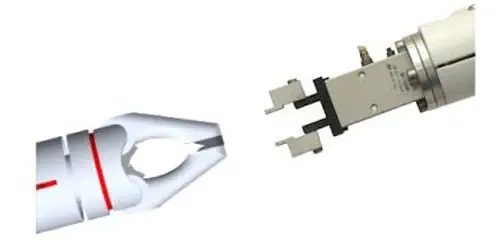

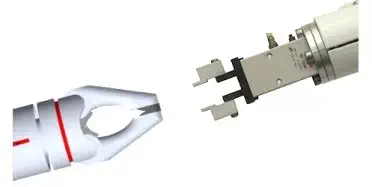

Grippers

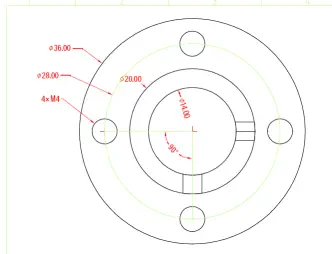

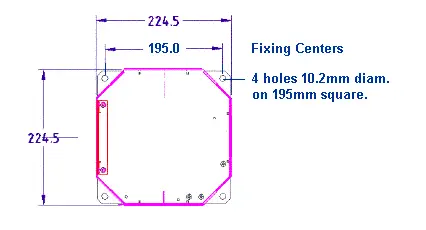

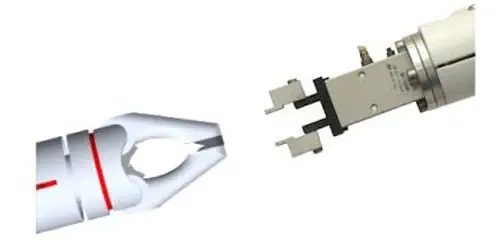

As standard the robots have a mounting flange (see diagrams below). End effectors currently include: electric gripper, SMC 10mm pneumatic gripper, vacuum pickups.

Note: pneumatic gripper is shown with special fingers made for a particular application, not part of the option. Fingers to suit the clients product may be made by the client or ST.

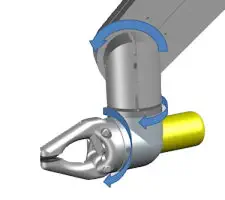

This is a simple solution that makes the 6th axis entirely optional as opposed to being an integral part of the design. Using a small motor and gearbox it is accurate and tough. Programming is an extension to the Cartesian functions of RoboForth. In this way the system can ensure the end effector points in the same direction (same orientation to X Y Z axes) as the robot moves around, or indeed in any direction you choose. See the 6th axis version in video

Linear track

Up to 3m length, using a powerful motor and two recirculating crossed roller bearings. High resolution or high speed options. See

video

12-axis system

Includes 2 R12 robots on a programmable carousel. Two robot controllers are interlinked to synchronize the two robots. The maximum number of axes in total is 13. Video available

here

Workspace Sentry System

The ST workspace sentry system comprises a module with 3 infra-red beams set at approx 30 degree angles. The beam works by sending out an infra-red pulse and timing how long it takes to get back. Because the beam is a pulse it is independent of background heat. The module connects into the emergency stop circuit of an ST robot controller. Breaking a beam has the same effect as pressing the stop button. The modules can be used singly or 2 or 3 modules may be daisy-chained.